WCS insights November 2023

Floating wind - This is how we scale for the energy transition

Ole Heggheim, CEO, Wind Catching Systems

Floating wind has a big part to play in the global energy transition, but will the land-based approach to scaling deliver the impact and cost reductions needed? There is a limit to the practical potential of onshore wind and solar installations. Most of the available wind resource offshore is found in areas where the water depths are too great for bottom-fixed installations. So, affordable, and scalable floating wind has to play a part in achieving the global energy transition.

The floating wind industry is in rough waters. The industry has been trying to take land-based wind generation business models and hope that they will happily float on the sea.

Supply chain issues plague the offshore wind industry in general, and floating wind projects around the world are hitting the breaks. There is no clear path to profitability. Hopes that costs would inevitably decline – following the solar path – have been dashed by supply chain constraints and inflation pressures. Flagship projects on both sides of the Atlantic are being put on hold.

The current approach to floating wind has been to transition an idea that works very well for both onshore and bottom-fixed installations, and float it.

The scaling method envisaged for floating wind originates in the aerodynamic approach that has proved so successful for land-based and bottom-fixed installations: Maximizing the energy yield per turbine has been essential to halving the cost for bottom-fixed wind installations over the last decade. An aerodynamic approach is not going to deliver the cost saving results for floating wind where the support structures cannot keep up with the turbine arms-race. Luckily, floating wind can be scaled with the number of standard turbines, avoiding the major challenges the industry faces as we push the limits of individual turbine capacity.

At Wind Catching Systems we come at the challenge of scaling from a hydrodynamic perspective: Maximizing the energy yield per floater is going to deliver the cost reductions needed for floating installations. In order to achieve this, you need to be able to scale up the units without breaking new technology barriers with each step. The answer to both challenges is a multi-rotor approach.

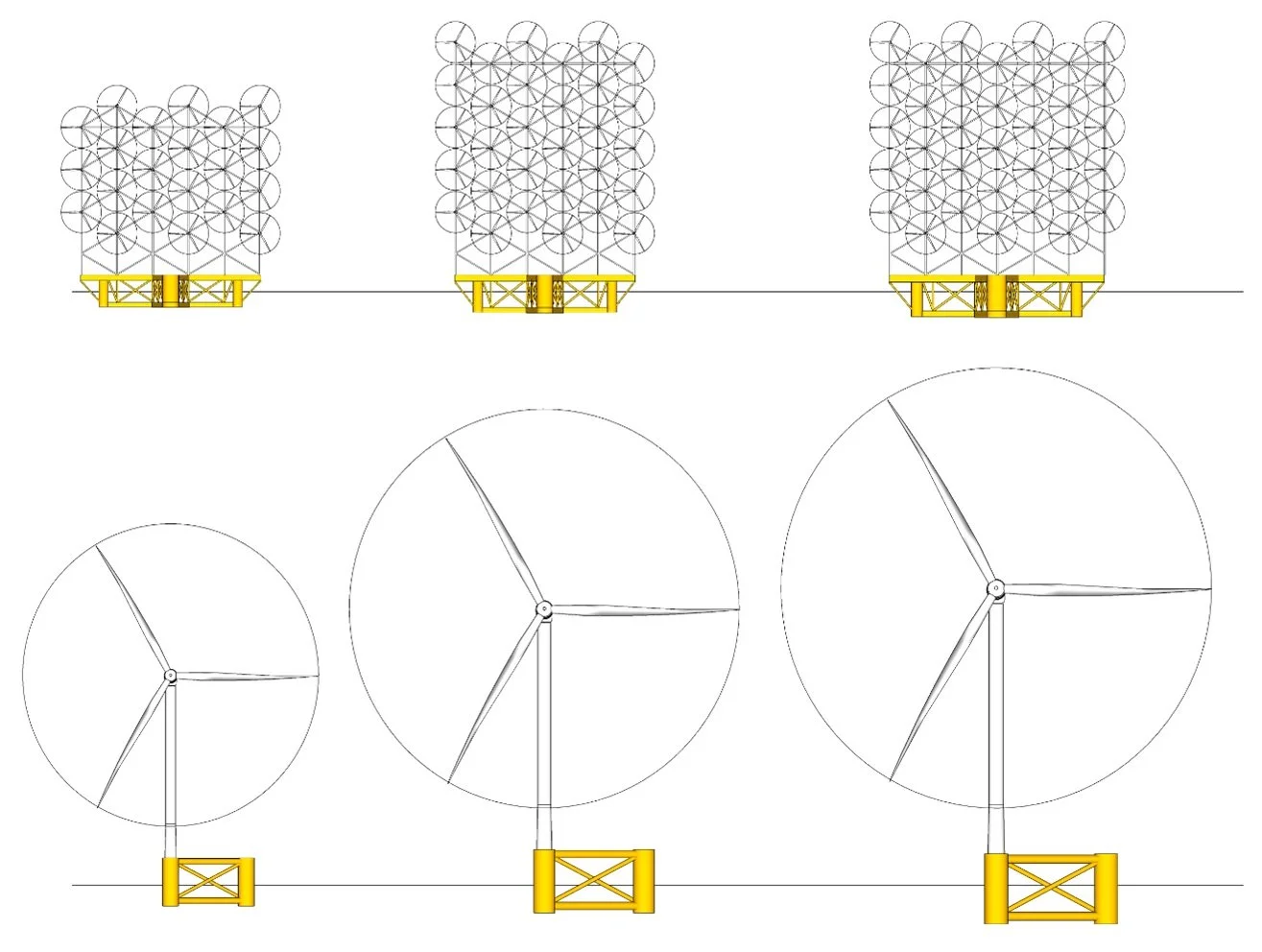

Our power capacity is scaled by changing the number of identical turbines, with no influence on turbine design, blade lengths or even the supply chain. This is opposed to single-rotor turbines, which meet significant new technology and logistical barriers with each increase in generator size, blade lengths and more. For onshore and bottom-fixed projects support structures are more easily adaptable to new models. For floating wind the systems for installation and maintenance are constantly running catch-up, and can never standardize to the degree where we get real cost reductions for the industry.

The Windcatcher technology is highly adaptable for project size and conditions. Operations and maintenance systems are based on the same core components and support structures across the model range. Irrespective of the size of the unit, mechanical and electrical components remain the same. This also means project developers can have strong confidence in supply chain and component availability.

Our mission at Wind Catching Systems is to establish floating wind as a sustainable and competitive energy source to support the global energy transition. To achieve this goal floating wind must scale up the energy yield per unit without sacrificing the ability to efficiently install and maintain the units.

In a hydrodynamic world the floater is the unit – and a multi-rotor approach is the way to deliver its potential.